- Home

- POLYTECH®

- What you can do

- POLYTECH® WALLS

POLYTECH® WALLS

What are POLYTECH® walls?

A quick, low cost, single-storey home construction system (Social House) without the need for a factory with production line as the wallsare cast directly on site, with the EPS lightweight concrete POLYTECH®.

Casting is carried out directly on site in formwork where steel reinforcement is already installed, if necessary, and the electrical and hydraulic systems.

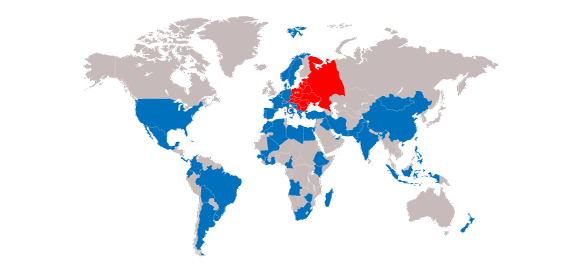

Where to use the technique POLYTECH® walls cast on site?

The on-site casting technique for walls and partitions can be used for the complete construction of low cost, single-storey homes (Social House) or for filling non load bearing walls where the load bearing structure (pillars and beams) are made with concrete or steel. In this application the thickness of the outer walls must not be less than 20 cm with minimum density of 400-500 kg/m³. While the partition walls can have a minimum thickness of 10 cm.

The on-site wall casting system is also suited for building fences and containment walls.

Walls made with POLYTECH® maintain a comfortable indoor climate, without thermal energy loss, also allowing considerable savings on the costs of use in environmental conditioning systems.

It also increases the transpirability of the walls preventing the formation of mould and considerably lightening the structure of the building.

How to cast POLYTECH® walls on site?

It is particularly easy to cast walls on site using the COISOIMPER system.

After installing the formwork, POLYTECH® is mixed and pumped by a complete machine, KOMPATTO R16 or Mp1, directly into the formwork.

From the next day the formwork can be removed, and it can be of any type as long as it is resistant to hydrostatic pressure and watertight.

To make POLYTECH® walls all you need are water, cement, polystyrene and TECH additive.

To increase the technical characteristics of POLYTECH® walls, the auxiliary additives, DSP XL and HDR can be added to the mixture.

Advantages of POLYTECH® walls cast directly on site.

There are multiple advantages to using the cast on site technique.

In the production phase:

– It is not needed a factory with production line

– Product stability during the production phase

– Easy change of density and dimension

– Contained investments and start-up costs

– Low energy consumption in production

In the transport:

– It is produced directly on site

In the construction site:

– Excellent quality/price ratio

– Easy and quick installation

– 100% recyclable

At the end of construction:

– Excellent thermal and acoustic insulation

– Fire resistance

– Energy savings

– Considerable mechanical strength

– Tearing strength for unit mounting

– Impact resistance

– Savings of up to 30% for domestic heating and cooling

– No need for insulating plaster

Machinery and additives for the production of POLYTECH® walls.

Equipments required for POLYTECH® walls.

COMPLETE PLANTS:

– KOMPATTO series

– K250 series

– Mp1 v3

– Mp250

Additives required for POLYTECH® walls.

ADDITIVES FOR POLYSTYRENE:

– TECH or TECH S

Optional equipments for POLYTECH® walls.

ACCESSORIES:

– Screw conveyor for cement CTC

– Electronic weighing system EWS

– Cart

– Grinding mill for EPS, M-EPS v20

Optional additives for POLYTECH® walls.

AUXILIARY ADDITIVES:

– DSP XL

– HDR

Request info

Contacts

Via Cassia zona ind.le Cesa

52047 Marciano della Chiana (AR)

Tel. +39.0575.842525

Fax. +39.0575.842800

info@coisoimper.com

CO.ISO.IMPER S.R.L. - Via Cassia, 52047 Marciano della Chiana (AR) - P.IVA 01275220513 - REA AR-94793 - Cap. Soc. 20.000,00 €

Copyright © 2024 | All rights reserved